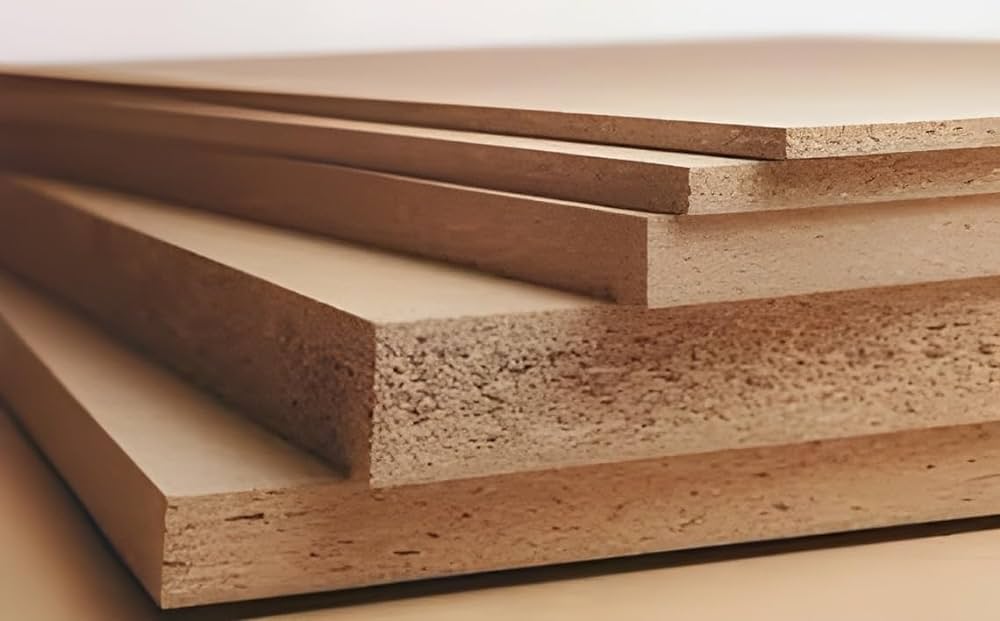

Comparing Different Grades of Particle Board: Which One Is Right for You?

Particle

board is a versatile and cost-effective material used in a variety of

applications, from furniture construction to interior design projects. However, not all

particle boards are created equal. Understanding the different grades of particle board

can help you choose the right one for your specific needs. In this blog post, we'll

explore the various grades of particle board available on the market and discuss their

strengths, weaknesses, and ideal uses.

Standard Particle Board :

- Standard particle board, also known as chipboard, is the most basic type available.

- Made from wood chips, sawmill shavings, and resin, it offers decent strength and

stability.

-

Ideal for applications where cost is a primary concern, such as low-budget furniture

or temporary fixtures.

-

Not suitable for areas with high moisture or heavy load-bearing requirements due to

its lower density.

Medium Density Fiberboard (MDF):

-

MDF is a higher-grade particle board made from finer wood fibers and resin.

-

It has a smoother surface compared to standard particle board, making it suitable

for painting and finishing.

-

Offers better dimensional stability and can be machined more precisely, making it

ideal for intricate designs and cabinetry.

-

However, it is still susceptible to moisture damage and may not be suitable for

outdoor or high-humidity environments without proper sealing.

High Density Fiberboard (HDF):

-

HDF is the densest and highest-grade particle board available.

-

Made from even finer wood fibers and higher resin content, it offers exceptional

strength and durability.

-

Resistant to warping, swelling, and moisture absorption, making it suitable for

areas prone to humidity or moisture exposure.

-

Commonly used in high-end furniture, kitchen cabinets, and flooring applications

where durability and longevity are paramount.

Moisture-Resistant Particle Board:

- Designed specifically to withstand moisture and humidity, moisture-resistant

particle board is treated with water-repellent chemicals during manufacturing.

- While it offers better moisture resistance compared to standard particle board, it

may still swell or warp if exposed to prolonged moisture.

- Ideal for use in kitchens, bathrooms, and other areas where moisture is present but

not in direct contact with the material.

Fire-Rated Particle Board:

- Fire-rated particle board is treated with fire-retardant chemicals to reduce its flammability and slow down the spread of fire.

- Commonly used in commercial buildings, hospitals, and other facilities where fire safety is a concern.

- While it provides an added layer of protection, it may not be completely fireproof and should be used in conjunction with other fire safety measures.

Choosing the right grade of particle board depends on various factors such as budget, intended use, and environmental conditions. While standard particle board may suffice for basic applications, investing in higher grades such as MDF or HDF can offer better performance and longevity. Consider the specific requirements of your project and weigh the pros and cons of each grade before making a decision. By selecting the appropriate grade of particle board, you can ensure the success and durability of your project.